Share Marshall Mix Design Lab Report. View Lab Report - 379142956-Marshall-Mix-Design-Lab-Reportdocx from MTR 241 at Seneca College.

Calculations For The Marshall Mix Design Of Bituminous Mixtures Pdf Free Download

KT-15 Ps aggregate percent by total dry weight of mixture.

. Sufficient Asphalt to cover all aggregates to ensure durability. In Malaysia the Marshall Mix Design has become the norm in the road industry. Section 15 Report 20 Figure 1 Example Mix Design Composite With and Without Mineral Admixture 23 Figure 2 Example Weigh Up Sheet 1 24 Figure 3 Example Weigh Up Sheet 2 25 Figure 4.

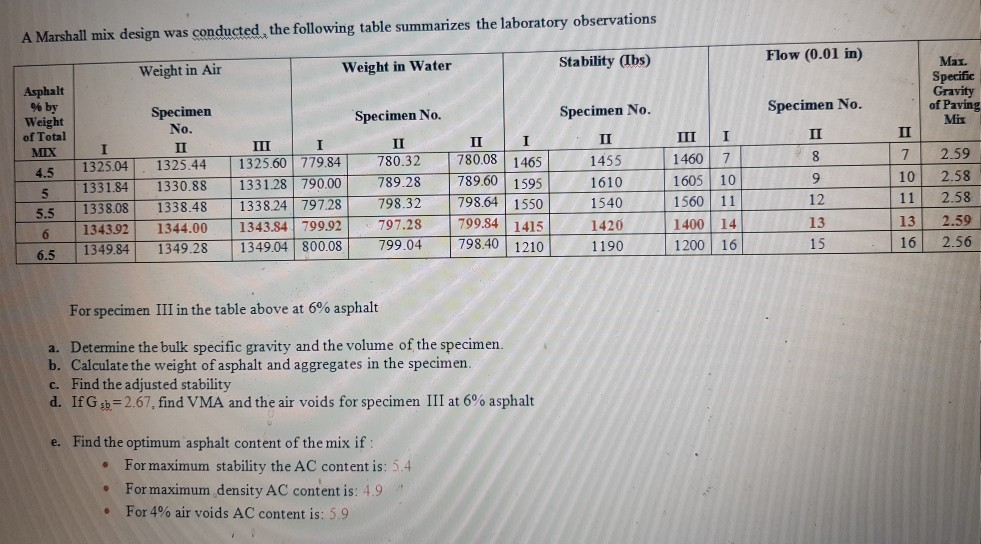

Compact three specimens at each of five asphalt contents spanning the expected optimum asphalt content. Before any bitumen mixes can be placed and laid on the road the aggregate and the binder types are generally screened for quality and requirement. Find the optimum bitumen content of the mix.

Report the type of sample tested laboratory sample or pavement core specimen Average maximum load in pounds-force of at least three specimens corrected when required. The Marshall method uses standard test specimens of 635 mm height by a 1016 mm diameter. 4 percent air void 3 percent bitumen content.

Lab mixing and compaction temperatures for all mixtures were selected in accordance with viscosity criteria stated by the Asphalt Institute in MS-2 U. Establish mixing and compaction temperatures from the viscosity-temperature chart. AGGREGATE SPECIFIC GRAVITIES AND ABSORPTION.

Gmb bulk specific gravity of compacted mixture. The specimen was loaded at a constant rate of starin of 508mmminute. Report the type of sample tested laboratory sample or pavement core specimen Average maximum load in pounds-force of at least three specimens corrected when required.

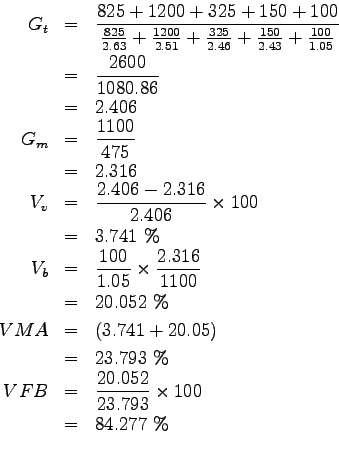

I density-voids analysis and ii stability-flow tests. The Marshall method criteria allows the engineer to choose an optimum asphalt content to be added to specific aggregate blend to a mix where the desired properties of density stability and flow are met. The results of Marshall test for five specimen is given below.

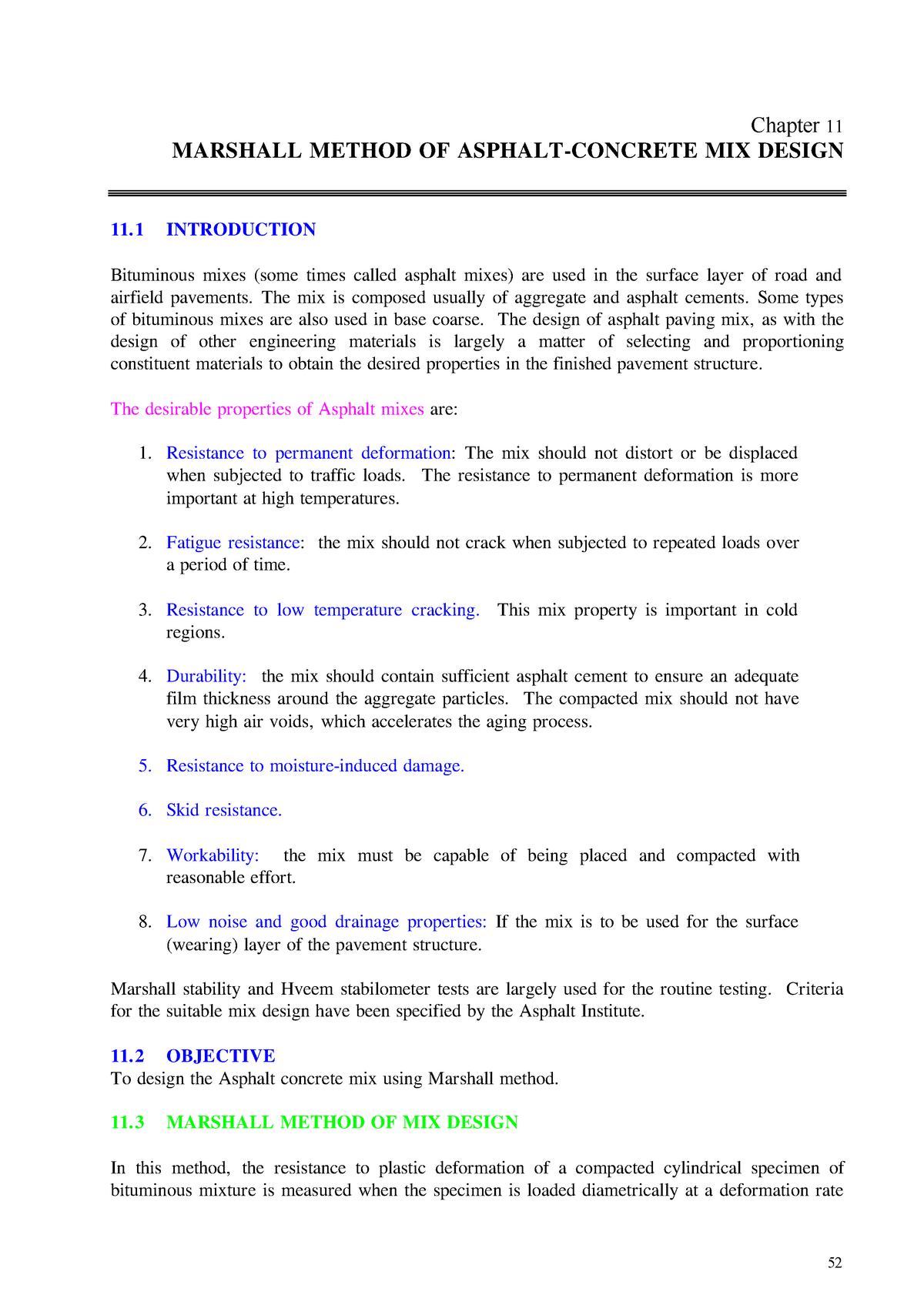

An asphalt mix must have. It uses standard cylindrical test specimens 64 mm high and 102 mm in diameter. MARSHALL MIX DESIGN10 INTRODUCTION The main purpose of the design process is to determine the optimum bitumen content OBC of each asphaltic mixture.

Marshall mix design lab report pdf. Create aggregate blend to meet gradation specifications. HK01 CIVIL ENGINEERING PROGRAM FACULTY OF CIVL ENGINEERING UNIVERSITY MALAYSIA SABAH KA31802 OF.

Interchangeable base plate and collar can be used on either end of compaction mould. These are prepared using a specified procedure for heating mixing and compacting the asphalt-aggregate mixture. Average flow value in hundredths of an inch twenty-five hundredths of a millimeter of three specimens Test temperature.

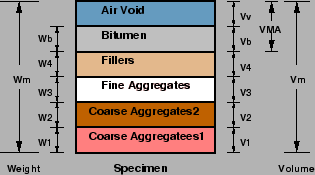

Consists of base plate forming mould and collar. Microsoft PowerPoint - 22 - Marshall Mix Design Author. Percent Air Voids Pa - The volume of air voids in a compacted mixture expressed as a percentage of the total mix volume.

There are two major features of the Marshall method of mix design. Solution Plot the graphs and find bitumen content corresponding to Max stability 5 percent bitumen content. Average flow value in hundredths of an inch twenty-five hundredths of a millimeter of three specimens Test temperature.

Marshall mix design lab report pdf. 6 Figure 1 sb Where. For preparing specimens of 10cm diameter and 635 cm height for Marshall testing.

The same mixcompaction temperatures were used for both the Marshall and SUPERP A VETM Level I mix design procedures. Stability of test specimens is the maximum load resistance developed by standard test specimen at 60C in Newton. If mix composition is determined as percent by weight of the total mixture.

VMA 100 - G P G mb s Eq. The marshall sample was soaked for at least 30-40 minutes in the water bath at 60C. Before any asphalt mixes can be placed and laid on the road the aggregate and the binder types are generally screened for quality and requirement.

Bruce Marshall Mississippi Highway Department Marshall Mix Design Steps 1. The Marshall stability of the mix is defined as the maximum load carried by the specimen at a standard test temperature of 60C. Then the sample was tested for Marshall machine to determine its stability and flow.

Approximately 15 samples are required. The stability value obtained was corrected by the appropriate coefficient in Table 2. For Marshall Rice and IMC will be performed as specified in Sections 8-10 11 and 13 respectively.

Considered for any mix design method. 4142020 14324 PM. This site is like the Google for academics science and research.

PREPARATION OF SPECIMEN Marshall Mould 1. Two principal features of Marshall Method of mix design are Density Void Analysis and Stability Flow Test of compacted test specimen. The two principle features of the Marshall method of mix design are a density-voids analysis.

The mixing temperature of the 6070 grade is about 165C. Of 50 mm per minute. VMA voids in mineral aggregate percent of bulk vol Gsb bulk specific gravity of aggregate.

Marshall Method of Mix Design Standard Asphalt Institute MS 2 The Marshall method of mix design is used to determine the optimum bitumen content of dense graded HMA mixes. Max 5 percent bitumen content. Approximately 15 samples are required to be prepared to determine the required Optimum Bitumen Content OAC.

Pdf Lab 7 Marshall Lab Procedure Tushar Zakir Academia Edu

Solved A Marshall Mix Design Was Conducted The Following Chegg Com

Refusal Density Mix Design Pdf

Pdf Comparative Evaluation For Mix Design Of Marshall And Superpave Methods

Marshall Stability Test For Bitumen Mixture We Civil Engineers

Marshall Mix Design Lab Report Pdfcoffee Com

Marshall Test Pdf Asphalt Road Surface

11 Marshaltest Chapter 11 Marshall Method Of Asphalt Concrete Mix Design 11 1 Introduction Studocu

11 Marshaltest Chapter 11 Marshall Method Of Asphalt Concrete Mix Design 11 1 Introduction Studocu

Free Pdf Download Marshall Mix Design Project Akansha Jagat Academia Edu

Design Mix Method Of Bitumenous Materials By Marshall Stability Method

Calculations For The Marshall Mix Design Of Bituminous Mixtures Pdf Free Download

Marshall Mix Design Question Pdf Marshall Mix Design Tutorial 1 A Mix Made With A Bitumen Content 6 By Mass S G 1 030 G Ml And An Aggregate Of Course Hero

Pdf Comparison Of Marshall And Superpave Asphalt Design Methods For Sudan Pavement Mixes

What Is Marshall Mix Design For Bituminous Materials Civil Engineering Portal Biggest Civil Engineering Information Sharing Website

Marshall Mix Design Question Pdf Marshall Mix Design Tutorial 1 A Mix Made With A Bitumen Content 6 By Mass S G 1 030 G Ml And An Aggregate Of Course Hero